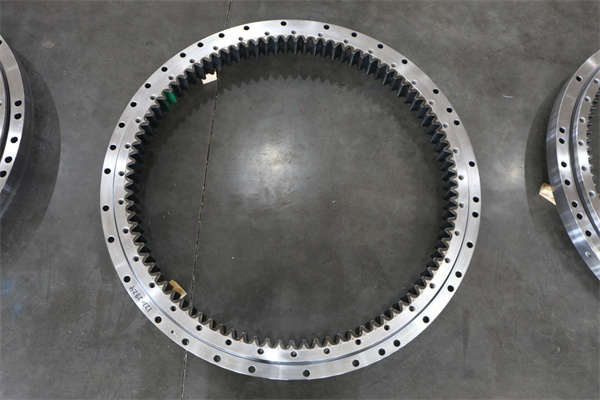

The excavator slewing bearing is one of the important parts of the excavator. Whether the slewing bearing can be properly disassembled will greatly affect the normal operation of the excavator. So, do you know how to properly disassemble and assemble the excavator slewing bearing?

1. Installation method of excavator slewing bearing

(1) Installation plane

Before installing the excavator slewing bearing, it is necessary to check the mark and certificate to ensure that the model of the slewing bearing used is correct. If there are welding beads, burrs, paint residues, etc. on the surface of the excavator slewing bearing , it should be removed in time. Make sure that the cleaning solvent does not enter the inside of the slewing bearing, and the solvent used cannot damage the sealing material of the slewing bearing. When installing, make sure that the installation surface is dry.

(2) Mounting the support

The roughness of the mounting surface of the mounting support shall be controlled within the allowable range and shall not exceed the standard value range.

(3) Positioning

The inner and outer raceways of the slewing bearing are equipped with a soft belt, which should be placed on both sides of the main load surface, that is, 90 degrees away from the main load area, and the soft belt is blocked or marked with an S mark.

(4) Check

When the installation is completed, it should be checked (usually with a feeler gauge) whether the slewing bearing matches the installation surface. If the match is not good, it should be filled with suitable materials. After the excavator slewing bearing is installed, the bracket is prohibited from welding.

…

Details can be accessed here: https://www.excavatorbearing.com/a/bearing-knowledge/Installation-of-excavator-slewing-bearing.html