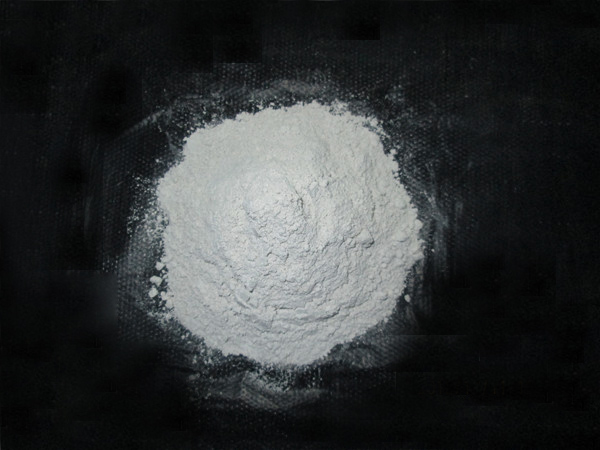

Calcium hydroxide is widely used in industrial production and life, but we often find that the effect of calcium hydroxide in use is not in line with the routine, so the deterioration of calcium hydroxide has become a problem that needs urgent attention. How to test calcium hydroxide Whether it has deteriorated, and the reasons for the deterioration of calcium hydroxide, we have introduced the following details, let’s find out together!

IDENTIFICATION METHOD OF CALCIUM HYDROXIDE DETERIORATION

1. Hydrochloric acid identification method

Take out some calcium hydroxide and add enough hydrochloric acid. If there is gas, it means that the calcium hydroxide has deteriorated.

2. Water identification method

Another method introduced by calcium hydroxide manufacturers is that after adding sufficient water, there are still insolubles, which also means that calcium hydroxide has deteriorated, because calcium carbonate is insoluble in water.

3. Carbon dioxide identification method

Calcium hydroxide is easily hardened with carbon dioxide in the air to form calcium carbonate. Therefore, we only need to determine whether there is calcium carbonate in the calcium hydroxide powder to know whether it has deteriorated.

REASONS FOR THE DETERIORATION OF CALCIUM HYDROXIDE

1. The temperature is too high

1. The temperature is too high

The reason for the deterioration is temperature, and increasing the temperature can cause thermal cracking or thermal cross-linking of calcium hydroxide. But the basic effect of heat is activation. Improve the oxygen diffusion rate and activate the oxidation reaction, thereby accelerating the oxidation reaction rate of calcium hydroxide, which is a common aging phenomenon – thermal oxygen aging.

…

Details can be accessed by clicking here:https://www.ly-gaifeng.com/blog/how-to-check-whether-calcium-hydroxide-has-deteriorated.html

(1) The steel plate of the main engine head adopts 45# steel plate with a thickness of 40mm;

(1) The steel plate of the main engine head adopts 45# steel plate with a thickness of 40mm;