專(zhuān)注生產(chǎn)石油機(jī)械配件制造廠家

統(tǒng)籌規(guī)劃、科學(xué)設(shè)計(jì)、標(biāo)準(zhǔn)制造、嚴(yán)格管理

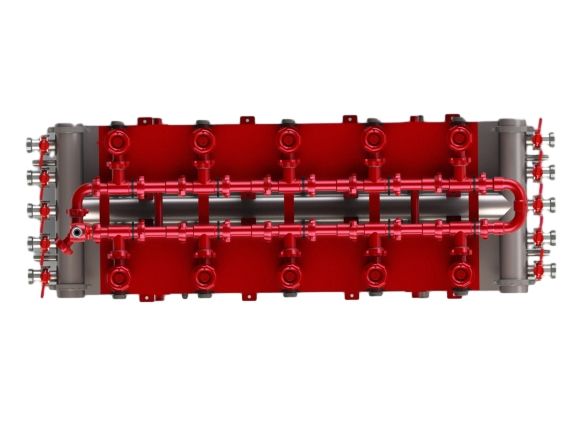

專(zhuān)注石油壓力管道、閥門(mén)、鉆機(jī)轉(zhuǎn)盤(pán)、鉆井鉆機(jī)系列配件研發(fā)、生產(chǎn)、銷(xiāo)售

內(nèi)黃縣石油機(jī)械有限責(zé)任公司成立于1992年,1999年改制為股份有限公司,位于河南省安陽(yáng)市內(nèi)黃縣城關(guān)鎮(zhèn)帝嚳大道與人民路交叉口向北600米路西,注冊(cè)資金1200萬(wàn)元,建筑面積15000平方米。公司設(shè)有七個(gè)科室:辦公室、財(cái)務(wù)科、技術(shù)科、質(zhì)檢科、生產(chǎn)科、銷(xiāo)售科、供應(yīng)科。三個(gè)車(chē)間:機(jī)加工車(chē)間、熱處理車(chē)間、安裝車(chē)間。公司擁有進(jìn)口和國(guó)內(nèi)加工中心、數(shù)控車(chē)床、磨床、刨床、銑床、插床、鏜床、中頻、高頻加熱淬火機(jī)床、大型井式爐、箱式電阻調(diào)質(zhì)爐、淬火爐、滲碳爐及高精度壓力試驗(yàn)、理化分析、無(wú)損檢測(cè)實(shí)驗(yàn)設(shè)備共計(jì)120余臺(tái)套,是生產(chǎn)石油機(jī)械配件的制造廠家。 公司從事石油壓力管道、閥門(mén)、鉆機(jī)轉(zhuǎn)盤(pán)、鉆井鉆機(jī)系列配件的研發(fā)、生產(chǎn)、銷(xiāo)售。主要產(chǎn)品有鉆機(jī)轉(zhuǎn)盤(pán)總成及鉆采特車(chē)系列配件。公司擁有中華人民共和國(guó)特種設(shè)備制造許可證、API6A、16C、ISO9001—2015國(guó)際質(zhì)量體系認(rèn)證證書(shū)、ISO14001-2015環(huán)境管理體系認(rèn)證證書(shū)、ISO45001-2018職業(yè)健康安全管理體系認(rèn)證證書(shū)和AAA信用等級(jí)認(rèn)證證書(shū)。本公司為中國(guó)石油天然氣總公司、中國(guó)石化物資裝備總公司一級(jí)網(wǎng)絡(luò)成員單位。產(chǎn)品銷(xiāo)售中原、勝利、華北、大港、南陽(yáng)、江漢、遼河、新疆等全國(guó)各油田,以產(chǎn)品質(zhì)量和良好的售后服務(wù)深受各油田用戶(hù)的好評(píng),連年被縣委、縣政府評(píng)為先 進(jìn)工業(yè)企業(yè)和納稅先 進(jìn)企業(yè)。

-

1999改制為股份有限公司

1999改制為股份有限公司 -

1200注冊(cè)資金(萬(wàn)元)

1200注冊(cè)資金(萬(wàn)元) -

15000建筑面積(㎡)

15000建筑面積(㎡) -

120 +制造檢測(cè)設(shè)備(臺(tái))

120 +制造檢測(cè)設(shè)備(臺(tái))

成為您信賴(lài)的石油裝備配件制造商

填寫(xiě)需求信息,我們會(huì)及時(shí)聯(lián)系您