Rotary sludge dryer

The main structure of the Rotary sludge dryer is a steam tube rotary drum type, which uses water vapor as a heat source to complete drying of lignite, coal slime and the like. Our company can design and manufacture according to user requirements and material specific conditions. Especially steam heating systems such as air intake, gas separation and backwater have unique innovations compared with traditional structures, which can effectively improve the condensate drainage.

The device is a cylinder that is mounted on the support device with a certain inclination and is driven by the transmission to rotate slowly. The material is added from the feeding end of the cylinder. Since the cylinder is installed obliquely, the material in the cylinder moves along the axis while rolling in the circumferential direction, and slowly flows through the entire cylinder from the feeding end of the cylinder, and discharges the cylinder at the discharging end. body. The water vapor enters from the rotary joint located at the discharge end of the drum, and then enters hundreds of tubes through the gas-dividing bag and the gas-dividing pipe. The condensed water in the pipe and the steam are discharged in the opposite direction through the gas-dividing bag and the rotary joint. During the process of turning and moving the material in the cylinder, high-efficiency heat exchange is performed with the outer wall of the tube to complete the drying process of the material.

Rotary dryer works:

The heat source of the dryer comes from the combustion device, and the dryer uses a downstream heating method. Therefore, the material to be dried is slipped from the feed box and the feed into the cylinder, that is, pushed back by the spiral plate. As the dryer is placed obliquely, the material flows to the rear end under the action of gravity and rotation. On the other hand, the material is repeatedly picked up by the copying plate, and is taken to the upper end and then continuously sown down, so that the material forms a uniform curtain in the cylinder. The curtain is fully exchanged with the hot air flow in the cylinder. As the material is repeatedly spread, the moisture contained is gradually dried, thereby achieving the purpose of drying.

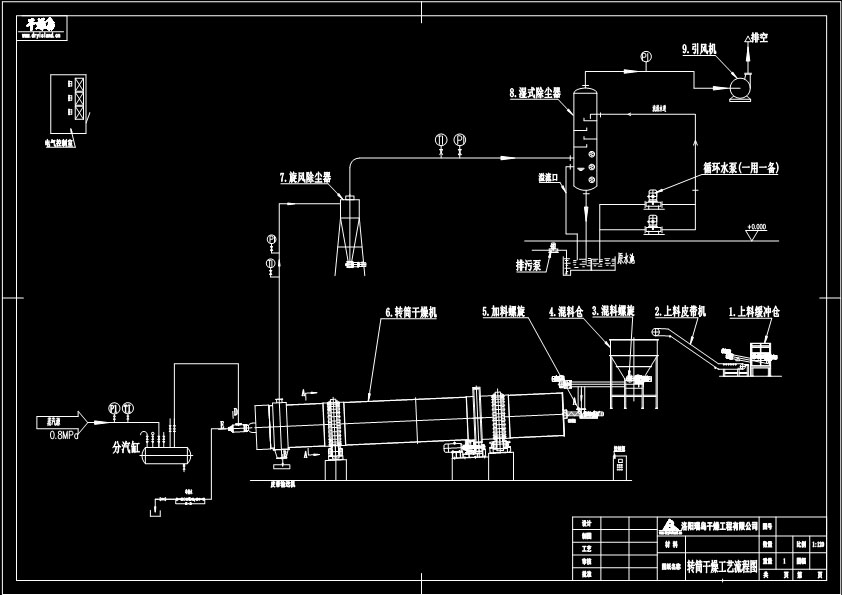

Process flow:

For lignite and slime drying, the RD steam tube drum drying system generally adopts the following process (the specific process can be adjusted according to the user’s raw material conditions and moisture content after drying and environmental protection requirements):

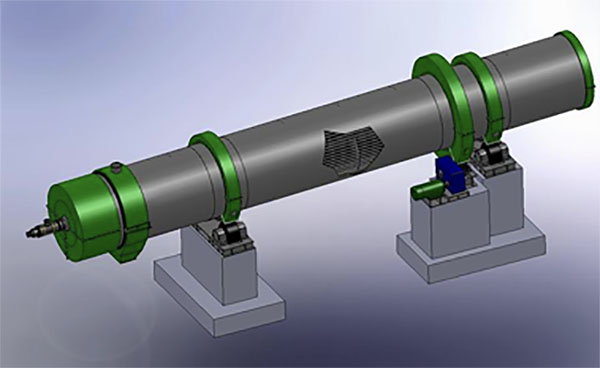

Rotary drying host structure (as shown below):

1. cylinder, 2. support device, 3. roller retainer device, 4. transmission device, 5. sealing device, 6. feed end air pipe and shroud, 7. discharge end air pipe and shroud, 8. Discharge port and discharge cover, 9. Roller and ring gear cover, 10. Rotary joint, 11. Air distribution package, 12. Steam tube assembly, etc.

Rotary sludge dryer specifications

|

Specification |

φ3.5*25M rotary sludge dryer | φ3.6*25M rotary sludge dryer |

|

Dry material |

Slime |

|

|

Moisture content before drying |

45% |

|

|

Moisture content after drying |

≤0.05% |

|

| Processing capacity |

25 tons / hour * 2 |

|